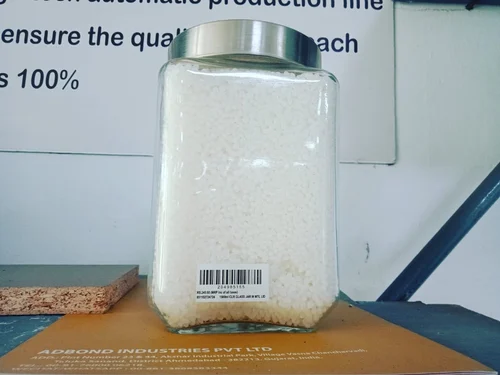

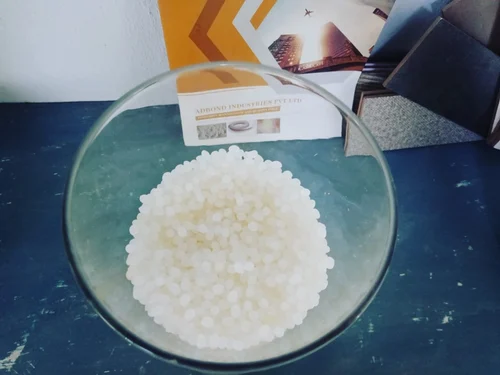

Adbond White Transparent Hotmelt Adhesive For Edgebanding Machine ADB-T303.3W

₹270.0

Product Specification

| Make | Adbond |

| Model Name | Adbond |

| Packaging Size | 25 kg |

| Packaging Type | PP Bag |

| Application Industry | Woodworking |

| Form | Granules |

| Grade Standard | Industrial |

| Strength | Low |

| Material Compatibility | PVC Edgeband |

| Chemical Resistance | Moisture |

| Color | White Transparent |

| Appearance | Particle |

| Open Time | 35 sec |

| Is It Eco Friendly | Yes |

| Shelf Life | 24 months |

| Country of Origin | Made in India |

| Minimum Order Quantity | 25 Kg |

Product Description

Adbond Industries Pvt. Ltd is Indochinese Company. Here we established a manufacturing plant of HOT MELT ADHESIVES & PVC EDGE BANDING & We also provide wood working materials & Machinery solution. We manufacture HOT MELT ADHESIVES & PVC EDGE BANDING in Various kind of code and We have large Range of in HOT MELT ADHESIVES & PVC EDGE BANDING .

For PVC edge banding we can customize all design and color to match your requirements. And we have almost 15years manufacture experience. Both products we have company in CHINA to support advance technical to India market.

We Hope That You Will Get in touch with us to visit us and start good business with your organization for mutual Benefits. So I am looking forward to more production deals with your organization.

About us :

Our company is located in one of the fastest growing cities in India, AHMEDABAD. It has modern industrial factories. It adopts the latest imported high-tech automatic production line and a series of advanced testing equipment for viscosity hot melt glue and tension hot melt glue. Our company specializes R&D, production and sales of hot melt glues for 15 years. The annual output each year can reach more than 10,000 tons.

The series products of hot melt glue are widely used in China, Japan, Germany, South America, Africa and other parts of the world, helping the company to establish a good reputation and brand. In order to better serve the needs of the Indian market and Indian customers, and to bring more knowledge, technology and services to Indian manufacturing, we made investments in the establishment of factories and production in AHMEDABAD, GUJRAT, India.

Company Culture: The only purpose of our company is to“ create value for customers”. Our company takes “integrity management and quality first ”as the management idea . The goal of our company is to pursue high quality products and services with modern scientific management methods.All our staff will work as one and have the courage to struggle against tremendous odds,we dare to innovate and strive for excellence.

(2) Main Application: Coating and Edge Bonding

Company Vision: Our company has been developing and producing products of hot melt glue for edge banding since last 15 years, from 2004. The company now has six series of adhesives including Wood working for hot melt adhesives, Hot coating melt glue series, Book binding adhesives, Packaging adhesives, Mattress adhesives and Pressure sensitive adhesives and so on. Products are widely used in all kinds of industries and exported to all over the world. Now we have successfully put our products and services into the Indian market, and invested in the establishment of ADBOND INDUSTRIES PVT Ltd., which is a production enterprise, in GUJRAT, India.

Company Advantages: India’s largest hot melt glue manufacturer, one of the most advanced equipment manufacturers.

We have the top foreign advanced research and development team to provide the best quality and most suitable hot melt adhesives solutions for furniture manufacturing enterprises.We have a 500 tons of warehouse capacity to provide the most comprehensive and rapid supply capacity;Save cost of inventory and time,and bring greater benefits for our customers.

- Description

- Additional information

- Reviews (0)

- Q & A

- Sustainability Remark

- More Offers

- Store Policies

- Inquiries

| Color | White |

|---|

You must be logged in to post a review.

Q & A

Low VOC (Volatile Organic Compound) adhesives are designed to minimize the release of harmful chemicals into the environment and improve indoor air quality. Their sustainability depends on several factors, including the composition of the adhesive, manufacturing processes, and their impact throughout the product lifecycle. Here are some key points to consider:

Reduced Environmental Impact: Low VOC adhesives emit fewer harmful chemicals into the atmosphere, which helps in minimizing air pollution and the formation of smog. This is particularly important for reducing greenhouse gas emissions and contributing to climate change mitigation.

Improved Indoor Air Quality: Low VOC adhesives are commonly used in indoor applications, such as construction and furniture manufacturing. By emitting fewer harmful chemicals, they help maintain better indoor air quality, which is beneficial for human health and well-being.

Material Composition: The sustainability of low VOC adhesives can be influenced by the materials used in their formulation. Ideally, these adhesives should be free from hazardous substances such as formaldehyde, toluene, and other volatile solvents. Environmentally friendly ingredients, such as water-based or plant-based alternatives, are often used in low VOC adhesives, enhancing their sustainability profile.

Manufacturing Processes: The sustainability of low VOC adhesives also depends on the manufacturing processes involved. Energy-efficient manufacturing techniques and the use of renewable energy sources can significantly reduce the environmental impact. Additionally, responsible waste management and recycling practices contribute to overall sustainability.

Product Lifespan: The durability and longevity of products bonded with low VOC adhesives are crucial for their sustainability. If the adhesive bond remains intact over an extended period, it reduces the need for frequent repairs or replacements, thus reducing waste and resource consumption.

Certifications and Standards: Look for third-party certifications and standards such as GreenGuard, LEED (Leadership in Energy and Environmental Design), or other recognized eco-labels. These certifications provide assurance that the low VOC adhesive meets specific sustainability criteria and has undergone rigorous testing.

Disposal and End-of-Life Considerations: Sustainable adhesive solutions should be designed to facilitate easy separation and recycling of bonded materials during the end-of-life phase. Adhesives that enable the recyclability of components or allow for efficient separation can contribute to a more circular economy.

By considering these factors, the sustainability of low VOC adhesives can be improved, making them a preferred choice for various applications while minimizing their environmental impact.

General Inquiries

There are no inquiries yet.

Reviews

There are no reviews yet.