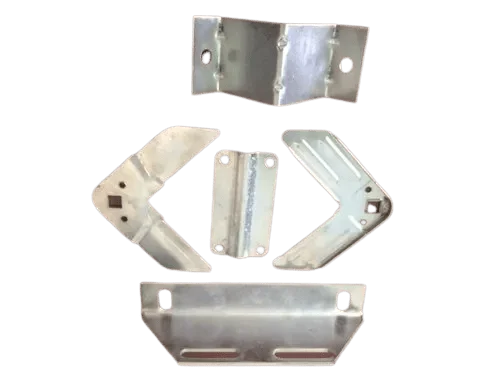

Sheet Metal Pressed Components, For Ac Ducting, Thickness: 01.00mm To 03.00mm

₹150.0

Our commitment extends to a comprehensive collection of superior Pressed Components, meticulously designed to meet your unique needs. These components are customized to perfection, ideal for AC ducting applications. Crafted from mild steel, they offer exceptional corrosion resistance and are finished with zinc plating for added durability. Ranging in material thickness from 1.00mm to 3.00mm, our products showcase a fine, burr-free finish through the power press processing method. They boast a striking zinc pacivation color, ensuring both aesthetics and functionality.

Our commitment extends to a comprehensive collection of superior Pressed Components, meticulously designed to meet your unique needs. These components are customized to perfection, ideal for AC ducting applications. Crafted from mild steel, they offer exceptional corrosion resistance and are finished with zinc plating for added durability. Ranging in material thickness from 1.00mm to 3.00mm, our products showcase a fine, burr-free finish through the power press processing method. They boast a striking zinc pacivation color, ensuring both aesthetics and functionality.

Furthermore, we offer Progressive or Compound Die Metal Press Parts of utmost quality, meticulously fabricated in accordance with international industrial standards. Our highly skilled and experienced professionals employ cutting-edge technologies to create these offerings. Competitive pricing, along with timely delivery assurance, makes these products a valuable choice.

Further Details:

Output Capacity: 10,000 kg. per month

Reviews

There are no reviews yet.