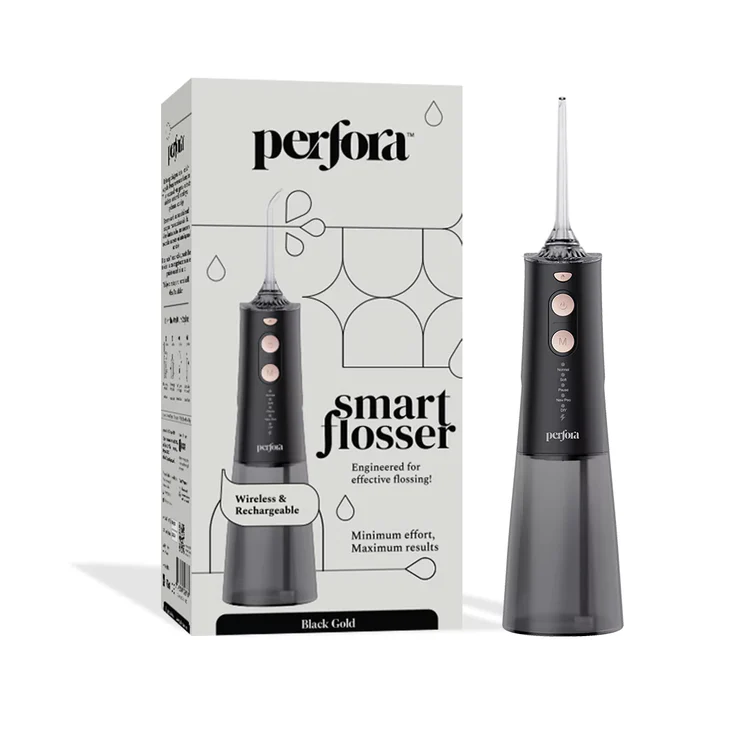

Smart Dental Flosser

Original price was: ₹3,999.0.₹2,599.0Current price is: ₹2,599.0.

- Portable and travel-friendly.

- Removes up to 99.9% of plaque

- 50% more effective than traditional string floss

- Reduces the risk of dental problems such as cavities and gum disease

You must be logged in to post a review.

Q & A

Factors Contributing to a Low Carbon Footprint of the Smart Dental Flosser 1. Materials Used: - Biodegradable or Recycled Materials: If the Smart Dental Flosser is made from biodegradable plastics or recycled materials, this significantly reduces its carbon footprint. Biodegradable materials require less energy to produce and degrade naturally without releasing harmful chemicals. - Minimalistic Design: A design that uses fewer materials will have a lower carbon footprint because it requires less raw material extraction and processing. 2. Manufacturing Process: - Energy Efficiency: Manufacturing facilities powered by renewable energy sources (e.g., solar, wind) or employing energy-efficient technologies reduce the carbon emissions associated with production. - Waste Management: Efficient waste management and recycling processes in manufacturing can also lower carbon emissions by reducing the need for raw material extraction and processing. 3. Supply Chain and Logistics: - Local Sourcing: Sourcing raw materials and components locally can significantly reduce transportation emissions. - Efficient Distribution: Optimizing logistics and using eco-friendly transportation methods (e.g., electric vehicles) can also reduce the carbon footprint associated with distribution. 4. Product Lifespan and Usage: - Durability: A longer-lasting product reduces the frequency of replacements, thereby reducing the overall carbon footprint over time. - Energy Consumption: If the flosser is electric, its energy efficiency during usage can also play a role. Energy-efficient motors and batteries with longer life cycles can minimize the product's operational carbon footprint. Scientific Analysis and References Materials and Manufacturing 1.Recycled Materials: - Study: "Environmental benefits of recycling – 2010 update" (WRAP, 2010) highlights the reduced carbon emissions from using recycled materials compared to virgin materials. - Impact: Using recycled plastics can reduce greenhouse gas emissions by up to 70% compared to using new plastics. 2. Biodegradable Plastics: - Study: "Life cycle assessment of biodegradable plastic packaging derived from genetically modified sugarcane" (Tabone et al., 2010) discusses the lower environmental impact of biodegradable plastics. - Impact: Biodegradable plastics can reduce the carbon footprint by minimizing landfill waste and reducing the emissions associated with traditional plastic production. Energy Efficiency in Manufacturing 1. Renewable Energy: - Study: "The carbon footprint of global energy consumption" (Hertwich & Peters, 2009) examines how renewable energy sources significantly lower carbon emissions in industrial processes. - Impact: Using renewable energy can reduce carbon emissions by over 80% compared to fossil fuels. 2.Energy-efficient Manufacturing: - Study: "Energy use in manufacturing: a comparison of different production processes" (Gutowski et al., 2006) highlights the importance of energy efficiency in reducing carbon footprints. - Impact: Implementing energy-efficient technologies can cut energy consumption and associated emissions by up to 30%. Supply Chain and Logistics 1. Local Sourcing: - Study: "The carbon footprint of global trade" (Cristea et al., 2013) emphasizes the emissions saved by localizing supply chains. - Impact: Local sourcing can reduce transportation emissions by up to 50%. 2. Eco-friendly Transportation: - Study: "Environmental and economic implications of distributed logistics networks" (DHL, 2016) discusses how optimizing logistics and using eco-friendly transport reduces emissions. - Impact: Using electric vehicles and optimizing logistics can reduce carbon emissions by approximately 20-30%. Conclusion The low carbon footprint of the Smart Dental Flosser likely stems from a combination of sustainable material choices, energy-efficient manufacturing processes, optimized supply chains, and energy-efficient usage. Each of these factors plays a critical role in minimizing the overall environmental impact of the product. For precise data and specific figures, access to the product's detailed sustainability report or life cycle assessment (LCA) would be necessary.

General Inquiries

There are no inquiries yet.

Reviews

There are no reviews yet.