Eco Friendly Home & Lifestyle, HandMade Bags, Home Decor Rural Livlihood

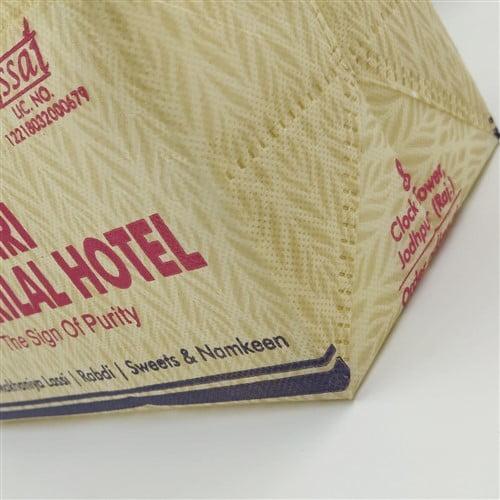

Shri Mishrilal Hotel Non-Woven Mini Parcel Bag W 9” x H 6” x G 6”

₹6.0

Designed & customized nonwoven non-laminated bag for mini parcel box with the floral theme.

Designed & customized nonwoven non-laminated bag for mini parcel box with the floral theme. The bag is blended with Cream & blue, Dark pink colors & is manufactured using the flexo printing process.

The bag is 100% recyclable & reusable.

Product Specifications

| Item | Description |

|---|---|

| Bag Colour | Ivory |

| Bag Size | S |

| Capacity (kg) | 2-3 kg |

| Material | Non Woven Fabric (100% Virgin) |

| Printed | Yes |

| Printing Process | Flexo Printing |

| Recyclable | 100% Recyclable |

| Reusable | Yes |

| Usage | Take Away Delivery Bags |

You must be logged in to post a review.

Q & A

There are no questions yet

1. Materials Used

The Eco Mini Parcel Bag is likely made from sustainable materials such as recycled plastics, biodegradable polymers, or natural fibers like jute or hemp. These materials are environmentally friendly compared to conventional plastic.- Recycled Plastics: Using recycled plastics reduces the demand for virgin plastic production, which is energy-intensive and involves significant greenhouse gas emissions. Recycling plastics also helps reduce plastic waste in landfills and oceans.

- Biodegradable Polymers: These materials break down more quickly than traditional plastics, reducing the environmental impact.

- Natural Fibers: Materials like jute or hemp are renewable, biodegradable, and have a lower environmental footprint during production.

2. Manufacturing Process

Eco-friendly manufacturing processes often involve reduced energy consumption, minimal use of harmful chemicals, and lower emissions.- Energy Efficiency: Manufacturing processes designed to be energy-efficient contribute to lower carbon emissions.

- Reduced Chemical Use: Limiting or eliminating harmful chemicals in the production process protects ecosystems and human health.

- Local Production: If the bags are produced locally, this reduces transportation-related emissions.

3. Lifecycle and Durability

The sustainability of a product also depends on its lifecycle and durability.- Long Lifespan: Products designed to be durable reduce the frequency of replacement, which in turn reduces the total environmental impact over time.

- Reusability: Reusable bags significantly cut down on single-use plastic bags, reducing waste and environmental damage.

Low Carbon Footprint of the Eco Mini Parcel Bag

1. Raw Material Sourcing

- Recycled or Natural Materials: As mentioned, using recycled or natural materials typically requires less energy than producing new plastic from petroleum. This reduces the overall carbon footprint associated with raw material extraction and processing.

2. Production Efficiency

- Energy-Efficient Manufacturing: Implementing energy-efficient technologies and practices in the production process lowers the carbon footprint.

- Renewable Energy: If renewable energy sources (like solar or wind) are used in manufacturing, the carbon footprint is further reduced.

3. Transportation and Distribution

- Local Production and Distribution: By manufacturing and distributing locally, the Eco Mini Parcel Bag minimizes transportation emissions. Shorter supply chains generally have a lower carbon footprint.

- Lightweight Design: A lightweight design reduces emissions during transportation due to lower fuel consumption.

4. End-of-Life Management

- Recyclability: If the Eco Mini Parcel Bag is designed to be easily recyclable, it reduces the environmental impact at the end of its life. Recycling consumes less energy than producing new materials.

- Biodegradability: For bags made from biodegradable materials, the end-of-life impact is reduced as they break down naturally without releasing harmful chemicals.

1. Gather Product Information

- Material: Identify the type of non-woven fabric used (e.g., polypropylene, polyester).

- Dimensions: Note the size and weight of the bag.

- Production Details: Obtain information about the manufacturing process, including energy sources and production methods.

- Usage and Lifespan: Consider how long the bag is used and any associated end-of-life disposal methods (recycling, landfill, etc.).

2. Calculate Carbon Footprint of Material Production

Non-woven fabrics are typically made from polypropylene or polyester. Here’s a simplified approach to estimate the carbon footprint of these materials: a. Material Production:- Polypropylene: The carbon footprint for producing 1 kg of polypropylene is approximately 2.0 to 2.5 kg CO₂e (carbon dioxide equivalent) (PlasticsEurope, 2021).

- Polyester: The carbon footprint for producing 1 kg of polyester is approximately 3.0 to 3.5 kg CO₂e (Textile Exchange, 2021).

- Weight of bag = 0.05 kg

- Carbon footprint for polypropylene = 2.0 to 2.5 kg CO₂e/kg

3. Calculate Carbon Footprint of Manufacturing

The manufacturing process includes energy use and other inputs. If available, use specific data from the manufacturer. If not, you can use general estimates:- Energy Use: Estimate the energy used in production. For non-woven fabric production, assume 1.5 to 3.0 kg CO₂e per kg of fabric produced (PlasticsEurope, 2021).

4. Calculate Carbon Footprint of Transportation

Estimate transportation emissions based on the distance traveled and mode of transport. For simplicity:- Transportation Emissions: Assume an average of 0.1 kg CO₂e per kg of product per 100 km traveled (based on truck transport).

5. Calculate End-of-Life Emissions

Consider how the bag is disposed of. If the bag is recycled, the emissions are lower compared to landfill disposal:- Recycling: Typically, 0.1 to 0.2 kg CO₂e per kg of product (assuming efficient recycling).

6. Total Carbon Footprint

Add all the calculated values: Total Carbon Footprint=Material Production+Manufacturing+Transportation+End-of-Life\text{Total Carbon Footprint} = \text{Material Production} + \text{Manufacturing} + \text{Transportation} + \text{End-of-Life} Calculation Example: Using the previous estimates:- Material Production: 0.1 to 0.125 kg CO₂e

- Manufacturing: 0.1 kg CO₂e

- Transportation: 0.025 kg CO₂e

- End-of-Life: 0.01 kg CO₂e

References and Scientific Explanation

- Life Cycle Assessment (LCA): Studies on LCA of products made from recycled plastics and natural fibers show significantly lower environmental impacts compared to traditional plastic products. For example, an LCA of recycled PET bags shows a reduction in greenhouse gas emissions by up to 50% compared to virgin PET.

- Source: A study published in the Journal of Cleaner Production highlights the environmental benefits of using recycled materials in packaging.

- Energy Efficiency in Manufacturing: Research indicates that energy-efficient manufacturing processes and the use of renewable energy can cut emissions by up to 30%.

- Source: International Energy Agency (IEA) reports on energy efficiency in industrial processes.

- Recyclability and Biodegradability: Products designed for recyclability or biodegradability contribute to lower carbon footprints as they reduce the need for new material production and lower the environmental impact of waste management.

- Source: Environmental Science & Technology journal provides insights into the benefits of recyclable and biodegradable materials.

No more offers for this product!

General Inquiries

There are no inquiries yet.

Reviews

There are no reviews yet.