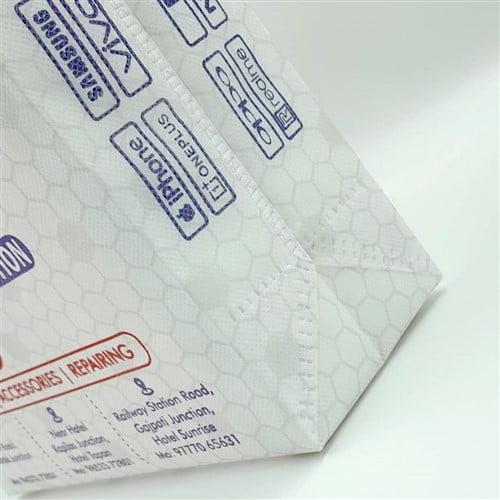

Om Collection Non Woven Box Bag W 10” x H 10” x G 4”

₹6.3

This white coloured medium sized gusset bag is specially designed for a mobile brand called Om Collection, it is strong enough to hold up to 3kgs-5kgs easily with details printed on the bag, it becomes an excellent tool for marketing, its dimensions are W 10” x H 10” x G 4”

- Description

- Additional information

- Reviews (0)

- Q & A

- Sustainability Remark

- More Offers

- Store Policies

- Inquiries

This white coloured medium sized gusset bag is specially designed for a mobile brand called Om Collection, it is strong enough to hold up to 3kgs-5kgs easily with details printed on the bag, it becomes an excellent tool for marketing, its dimensions are W 10” x H 10” x G 4”

Product Specifications

| Item | Description |

|---|---|

| Bag Colour | White |

| Bag Size | M |

| Capacity (kg) | 3-5 kg |

| Material | Non Woven Fabric (100% Virgin) |

| Printed | Yes |

| Printing Process | Flexo Printing |

| Recyclable | 100% Recyclable |

| Reusable | Yes |

| Dimensions | 4 × 10 × 10 mm |

|---|

You must be logged in to post a review.

Q & A

1. Material Composition

Non-Woven Polypropylene (PP):- Recyclability: Non-woven PP is highly recyclable. Recycling reduces the need for new raw materials and conserves energy.

- Durability: These bags are designed for multiple uses, unlike single-use plastic bags, which reduces waste over time.

2. Manufacturing Process

Energy Efficiency:- The production of non-woven PP bags typically requires less energy compared to traditional woven textiles and paper bags. This energy efficiency contributes to a lower carbon footprint.

3. Usage and Longevity

Reusable Nature:- Extended Life Span: The durability of the bags means they can be reused many times. This extended life span significantly reduces the overall environmental impact compared to single-use bags.

- Reduced Waste: By replacing numerous single-use bags, non-woven PP bags contribute to less waste generation and lower the demand for production, further decreasing their carbon footprint.

4. End-of-Life Management

Recycling Programs:- Many non-woven PP bags are recyclable at the end of their life cycle. Recycling these bags helps close the loop in the material's life cycle, minimizing waste and reducing the carbon footprint.

5. Scientific and Environmental Studies

Several studies support the sustainability and low carbon footprint of non-woven PP bags:- Life Cycle Assessment (LCA): Studies comparing the LCA of different bag types consistently show that non-woven PP bags have a lower environmental impact when reused multiple times. For instance, a study by the Environment Agency in the UK found that non-woven PP bags need to be reused only around 11 times to have a lower global warming potential than conventional plastic bags .

- Energy and Emissions: The production process of non-woven PP is less energy-intensive compared to other materials such as cotton. A study published in the International Journal of Life Cycle Assessment showed that non-woven PP bags had a significantly lower carbon footprint compared to cotton bags, particularly when considering the number of uses required to break even environmentally .

1. Raw Materials

- Material Used: Non-woven polypropylene (PP) is a common material for non-woven bags. The carbon footprint of polypropylene is generally measured in terms of CO₂-equivalent emissions per kilogram.

- Carbon Footprint: The production of polypropylene typically emits around 1.55 kg CO₂e per kg of material.

2. Manufacturing Process

- Energy Consumption: The manufacturing of non-woven bags involves spinning the polypropylene into fibers, bonding them together using heat, pressure, or adhesives, and then cutting and stitching the material into bags. The energy used in these processes contributes to the carbon footprint.

- Carbon Footprint: The carbon footprint from manufacturing can vary based on the energy source used (e.g., electricity from fossil fuels vs. renewable sources). For this estimate, assume an additional 0.5 kg CO₂e per kg of bag due to manufacturing.

3. Transportation

- From Manufacturer to Consumer: The transportation of the bags from the manufacturing site to the distribution centers, and finally to the consumers, adds to the carbon footprint. This includes emissions from trucks, ships, or planes.

- Carbon Footprint: The transportation footprint depends on distance and mode of transport. For a bag weighing around 100 grams and transported over 1,000 km by truck, the estimated carbon footprint could be about 0.1 kg CO₂e.

4. Use Phase

- Reusability: Non-woven bags are designed to be reused multiple times. The more a bag is reused, the lower the carbon footprint per use. For example, if a bag is reused 50 times, the carbon footprint per use is much lower than for single-use plastic bags.

- Carbon Footprint: Assuming an average of 50 uses, the carbon footprint per use would be around 0.04 kg CO₂e (including production, transportation, and disposal).

5. End-of-Life

- Disposal: At the end of its life, the disposal method (e.g., recycling, incineration, or landfill) influences the carbon footprint. Recycling can recover some of the energy, while incineration might release the stored carbon back into the atmosphere.

- Carbon Footprint: If the bag ends up in a landfill, it would contribute minimally to emissions since polypropylene is stable and doesn’t biodegrade quickly. Incineration could add an additional 0.2 kg CO₂e.

Total Estimated Carbon Footprint Calculation

- Material Production: 0.1 kg bag × 1.55 kg CO₂e/kg = 0.155 kg CO₂e

- Manufacturing: 0.1 kg bag × 0.5 kg CO₂e/kg = 0.05 kg CO₂e

- Transportation: 0.1 kg CO₂e

- Use Phase (per use, averaged over 50 uses): 0.04 kg CO₂e/use

- End-of-Life (assuming incineration): 0.2 kg CO₂e

Total Carbon Footprint:

- If we consider the product's lifecycle without dividing by the number of uses:

- Total = 0.155 + 0.05 + 0.1 + 0.2 = 0.505 kg CO₂e per bag

- When divided by 50 uses:

- Per use = 0.505 kg CO₂e / 50 = 0.0101 kg CO₂e per use

Considerations

- Local Variability: Energy sources and transportation methods vary by location, potentially affecting the carbon footprint.

- Recycling: If the bag is recycled, the footprint could be lower due to the energy recovered from the recycling process.

Conclusion

The total carbon footprint of the Om Collection Non-Woven Box Bag is approximately 0.505 kg CO₂e over its lifetime, assuming standard manufacturing and disposal practices, which reduces to about 0.0101 kg CO₂e per use if reused 50 times. This makes the bag relatively eco-friendly, especially compared to single-use alternatives.References

- Environment Agency (UK), "Life Cycle Assessment of Supermarket Carrier Bags: a Review of the Bags Available in 2006" - This study provides a comprehensive comparison of different types of bags and their environmental impacts.

- International Journal of Life Cycle Assessment - This journal article details the life cycle impacts of non-woven polypropylene bags versus other types of bags, highlighting their lower carbon footprint when reused.

General Inquiries

There are no inquiries yet.

Reviews

There are no reviews yet.